The company is having all the required infrastructure to manufacture the products as per WHO cGMP requirement and complies to EU GMP norms. The company has a built up area of about 120,000 sq. feet for production and storage of its products spread over 6000 sq. meters of Area.

The infrastructure includes dedicated HAVC systems with environment control (temp and humidity) at individual production steps and auxiliary area’s. Complete water management system with loop, separate storage and supply management system for each categories of drugs.

Services including compressed air, refrigeration, electricity generation, purified water plant, distillation plant, ETP plants and boiler for steam generation are provided in the engineering block.

Water Management System

Pace Biotech fully understand that water is an essential ingredient to pharmaceutical manufacturing process. Once purified, purified water or water for injection must be stored and distributed in systems appropriately designed, installed, commissioned and validated. Controlling the water quality in the distribution loop to ensure delivery to the point of use at the required flow and temperature can be challenging, that why Pace Biotech had installed sustainable, energy-efficient solutions to utilise the Water Manager Process.

Objective for Water Management System at Pace Biotech:

• Maintain water quality within acceptable limits

• Deliver water to the points-of-use at the required flow and temperature

• Minimize capital investment and operating expenses

• Ease validation of all equipment, spare parts and service kits

HVAC System

Pace Biotech had a complete setup of HVAC systems, which are essential components in the functionality and appeal of all modern buildings. We have Well-designed and efficient HVAC systems go well beyond ensuring comfortable temperatures and fresh air for facilities. As HVAC system play a key role in the production and testing processes of a broad spectrum of industries.

HVAC systems play a crucial role in pharmaceutical engineering and manufacturing because they have a direct impact on the production environment. Optimized HVAC units can help pharmaceutical companies manage airborne contaminants, pass inspections, and remain CGMP-compliant, and more.

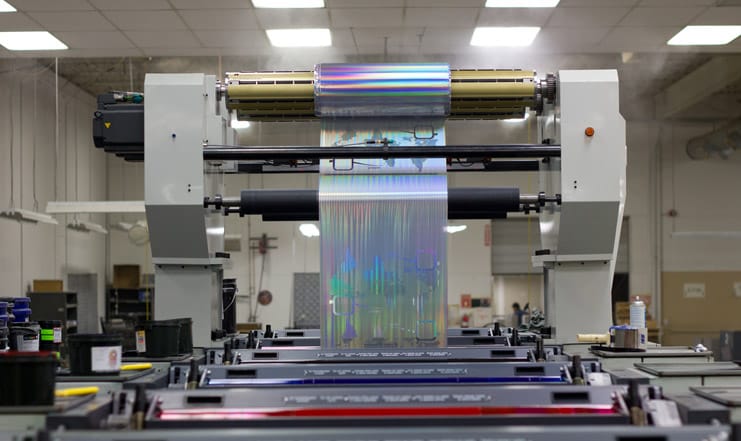

Printing & Packing

Pace Biotech have its own facility for the Printing and Packing of All type of Medicine we manufacture. Pace Biotech is fully dedicated towards development and enhancement of its pharmaceutical printing and packaging solutions. We are highly committed to print innovative materials that make it easier for your customers to get vital information and provide superior quality Pharma packaging solutions. We follow ISO standards to achieve consistency in all print processes. In short, Pace Biotech is the all-in-one solution the manufacturing of Injection & eye drop with printing and packaging.

The major functions of packaging include:

• Product Identification: Packaging helps consumers to identify the products.

• Product Protection: Packaging protects the internal contents of the product from breakage, leakage or spoilage.

• Product Promotion: Custom product labels are used for promotion and drawing the attention of clients.